Imaging Inspection Systems

Based on our well known and state-of-the-art research imaging systems LaVision is offering customized imaging inspection (inspex) systems setting industrial process control to a new level. Our broad toolkit of (laser) imaging techniques and systems allows us to cover a wide range of such process visualization applications covering air flow monitoring up to in-situ particle inspection.

Based on our well known and state-of-the-art research imaging systems LaVision is offering customized imaging inspection (inspex) systems setting industrial process control to a new level. Our broad toolkit of (laser) imaging techniques and systems allows us to cover a wide range of such process visualization applications covering air flow monitoring up to in-situ particle inspection.

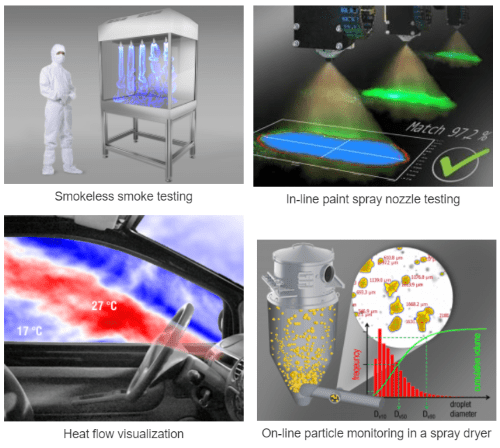

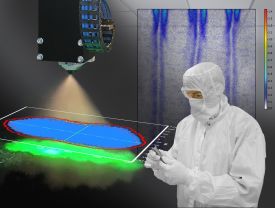

While machine vision systems mainly identify, inspect and sort parts, LaVision’s inspex systems are designed to monitor air and heat flows, sprays and particles in critical industrial process applications. Examples are:

- flow control in cleanrooms and flow boxes

- heat flux imaging in air conditioning applications

- spray plume profiling in spray nozzle tests

- particle (powder) characterization in spray dryers

The systems measure the process parameter(s) mostly in-line and in real-time with high spatial and temporal resolution. The systems are fully integrated in the process environment supporting simplified operation using an intuitive and customized user interface. The highly reliable lighting, imaging and optics modules are field changeable following the highest industrial quality standards. The modular design allows flexible solutions for even demanding customization requirements.

Applications: