Liquid Permeability Tester (LPT400)

The Liquid Permeability Tester (LPT 400) is designed to determine the liquid permeability and the Silt Density Index (SDI) in technical materials in a pressure range between 50 mbars and 4 bars.

A fully automatic program runs the selected test. The liquid is collected in a receptacle and the weight recorded by a balance is automatically transferred to the operating software, which calculates the liquid permeability.

MEASUREMENTS

- Liquid permeability

- Possibility to perform single or up to 3 measurements simultaneously (at one constant pressure level or on varying pressure levels).

- Duration of each cycle: up to 10 min.

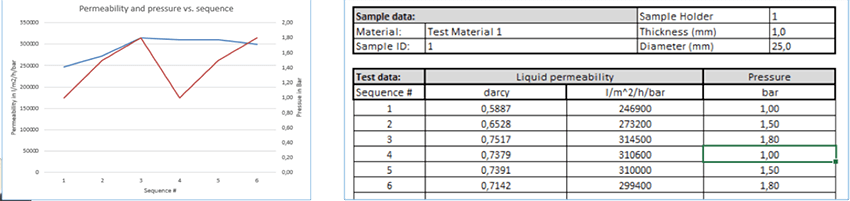

- Real time permeability vs time graphic display

- Permeability results are displayed in Darcy and in l/(m2*h*bar)

SILT DENSITY INDEX (SDI)

SDI measures the percent drop per minute in the flow rate of water through a filter, averaged over a period of time.

- In each cycle, the system measures the time required for 500 ml of fluid to pass through the sample, following by sample flushing step for 15 min before starting the next cycle.

- Possibility to carry out up to 12 repeated cycles.

High Throughput Gas Separation (HTGS)

The new High Throughput Gas Separation (HTGS) system is a device designed to run up to 16 different membrane-based separations of variable single and mixed gas feeds simultaneously. Up to 5 gases (O2, CO2, CH4, N2 and H2) can be mixed at a set flow. The on-line analysis option permits screening mixed gas selectivities, in comparison to single gas permeation experiments.

Ideal for measuring:

- Membrane permeability: single and mixed gas

- Membrane selectivity: mixed gas

- Physical ageing and plasticisation effects

- Long term membrane performance (up to several days)

High Throughput Membrane Testing

(SPIDER™)

The High Throughput (HT) dead-end filtration module for single feed liquid filtration, SPIDER™ is built in stainless steel and it is suitable for both water or solvent based feed solutions. In one single experiment it is possible to carry out either 8 or 16 simultaneous dead-end filtrations (depending on the SPIDER™ model), which supposes an extreme gain of time compared to conducting the same experiments one by one with a single cell.

The most important features of the SPIDER™ include:

The most important features of the SPIDER™ include:

- Common feed reservoir for the multiple membranes tested in the same run.

- Magnetic stirring ensuring a homogenisation and reducing concentration polarisation and membrane fouling.

- Total feed volume on demand.

- Full safety models available up to 40 bar.

- Optional heating by using a hot stirrer bottom plate.

Some examples of applications include:

- Water desalination.

- Membrane optimization for micro pollutants (e.g. drugs and/or colorants) removal from water.

- Recovery of high added value products (e.g. homogeneous catalysts).

- Membrane molecular weight cut-off characterisation tests using standardized polymers (e.g. PEG, PS) with known molecular weights and radii in different solvents.

- Solvent permeability characterization tests.

- Quality control.

Different solutions are available to better suit the needs of our customers. The most common version is the SPIDER™ with a sample holder with 8 membrane positions of 22 mm Ø for operating pressures up to 40 bar.